Bafang 100mm BBSHD shimano press fit 41mm diameter 89.5mm- 92mm width to BSA/JIS adaptor.

The BBSHD motor is designed for JIS/BSA threaded bottom bracket shells. If you have a 2012 and newer bike chances are you may have a Shimano Press Fit bottom bracket shell. Full suspension mountain bikes such as the Giant Trance and Giant Anthem models have an ideal frame for battery placement, but motor installation was not an option due to the bottom bracket and motor incompatibility. We are able to fit BBS02 and BBSHD motors in the 2011 and older Giant Trance and Giant Anthem bikes because they use a threaded BSA bottom bracket, but were unable to install mid drives into the newer models after the BB shell design changed to press fit. To solve this we custom machine an adaptor making it possible to install a 100mm wide BBSHD 1000 watt motor into the PF41 89.5mm-92mm wide BB shell. *Not intended for use on Carbon frames where shell may be too thick for motor clearance, intended for aluminum frames only.*

Intended for BB Shells with the following:

A very common bearing we see in these shells is the SM-BB71-41. This press fit bearing cartridge is another thing you can look for to determine if your bike has the compatible shell this adaptor is designed to work with.

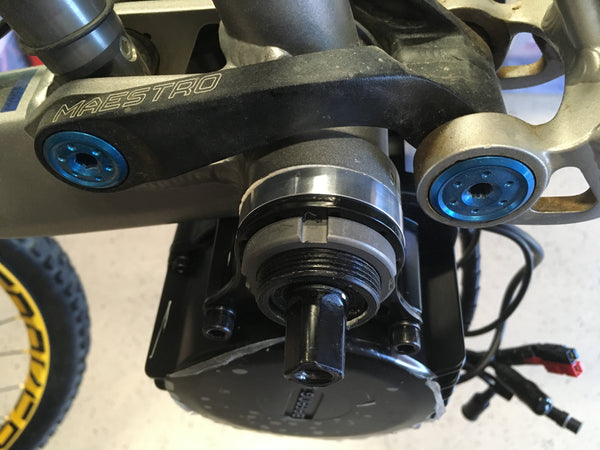

Seen below, is a 2012 Giant Trance X4 that will soon be receiving a BBSHD.

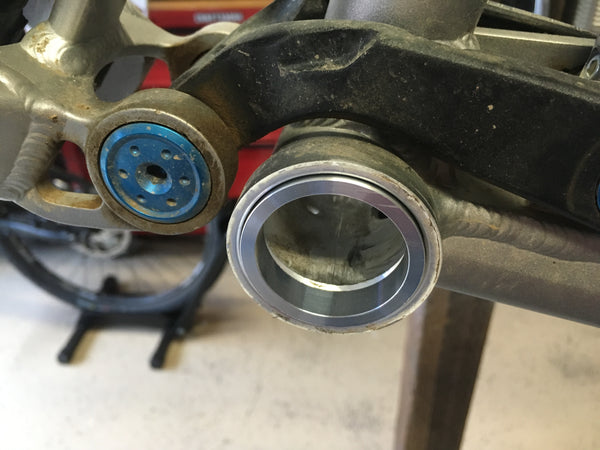

Its a 2 piece adaptor machined from 6061 aluminum designed to fit without needing a press and easily slides over the motor spindle shaft into the Shell's bearing races. You have the option of using Loctite 638 recommended for the adaptors gap clearance, but its completely optional. Our test results have shown it is not needed due to the way everything fits together when the M33 lock rings are tightened securely. The adaptor has been carefully designed and machined to fit a 100mm motor into a 89.5mm width PF41 shell without requiring additional spacers. This makes for a secure mechanical mount because the clamping force of the M33 lock rings compress the adaptor pieces against the non drive side shell face and the drive side bearing race wall. If shell is 92mm wide all that is needed are 2.5mm spacers on the two bolts between the fixing plate and motor body.

Drive side.

Non drive side.

Tighten up M33 lock rings to at least 60 Nm. Motors tend to fall because of improper torque of the M33 lockring. Complaints on the internet about the motor moving are caused because the installer has not properly tightened the lock ring. The compression of the M33 lock ring is what holds the motor up against the frame and prevents it from dropping.

Plenty of threads left for second lock ring and no spacers needed. Clean and mechanically sound install.